why cema screw conveyors ?

Screw Conveyors are one of the oldest and simplest devices used

for the movement of bulk materials. Our screw conveyor systems are

compact and easily adapted to congested locations. They can be

used as a mixer or agitator, mixing and blending dry or wet

ingredients. Screw conveyors are available in a wide variety of

materials resistant to corrosion, abrasion, and heat. Horizontal,

inclined, or vertical conveyors are also available.

-Inlet

is always control fed

-Trough loading of

15, 30, and 45%

-Volumetric conveying

device

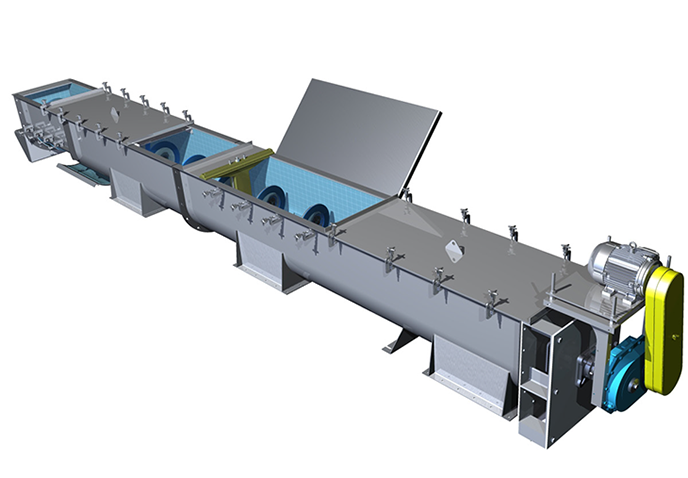

Multi Screw Conveyors

are used as screw feeders and may consist of twin, triple, or

quadruple screws, side by side. They provide a means of moving a

wide variety of material from bins or hoppers at a constant and

controlled rate of flow.

The inlet is usually flooded with

material (100% loaded)

Volumetric metering device

Ribbon Flight Conveyors consist of sectional flights,

butt-welded to form a continuous helix. The flights are secured to

the center pipe by supporting legs.

Ribbon flight conveyors are used to convey

tacky, gummy, or viscous substances, or in applications where the

material tends to adhere to the flighting and pipe.

Paddle

Screw Conveyors are used in applications where material needs to

be mixed before reaching its deStination. Adjustable paddles

provide complete mixing action and controlled material flow.

Conveying action can be controlled by adjuSting the angle of the

paddles.

Screw Feeders move a wide variety of material from

bins or hoppers at a constant and controlled rate of flow. One or

more tapered or variable pitch screws convey the material at the

required rate. Screw feeders are available in a variety of types

to suit specific materials and applications.

-Inlet

is always flood loaded

-100% trough

loading at inlet

-Volumetric metering

device

Shaftless Screw Conveyor

systems are used in applications where particle sizes are large.

They do not require hanger bearings because there is no center

pipe. Typical applications include bottling plants, rendering,

recycling plants, and wastewater treatment.

Transfer Sticky

or viscous bulk materials from one location to another

Conveyor

or feeder design

Volumetric conveying or feeding device

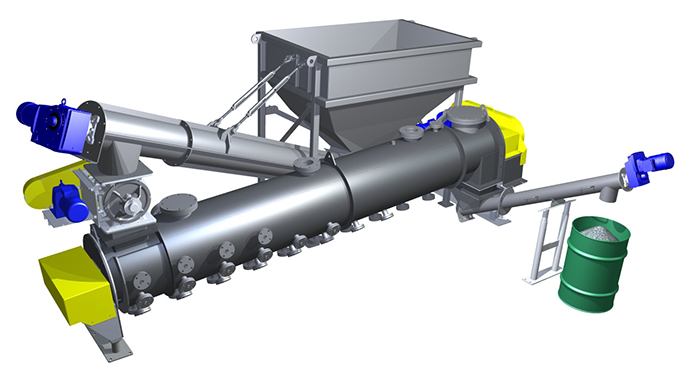

The DOSERAY is used to separate, classify,

and dewater grit from wastewater and grit slurries.

-Heavy-duty

design and construction

-Large settling

basin separates solids from liquids

-Typically

used in municipal wastewater applications

-High-torque

drive to handle upset conditions

-Support

legs for elevation requirements

Heat

Transfer Screw Conveyor systems cool or heat bulk

materials during conveyance. These units feature special tubular

jacketed housings.

-Heat transfer

mediums include water, glycol, steam, and hot oil

-Indirect heat transfer device

-Available in hollow-flight design

Pressurized

Screw Conveyors use tubular or pipe housing with

ANSI flanges, or a reinforced U-trough. This type of conveyor is

used for conveying various types of chemicals, and in

fire-suppression applications.

PDF BROCHURE

The five steps are:

Establish characteriStics of the bulk material to be conveyed.

Determine conveyor size and speed based on capacity.

Calculate horsepower requirements.

Verify

torque rating of components.

Select conveyor components.

Advantages of UsIng Screw Conveyors

Ideal for conveying dry to semi-fluid bulk materials – free

flowing to sluggish

Cost-effective when compared to other

conveying devices such as belt, pneumatic or aeromechanical

Efficiently distributes bulk

materials to various locations using multiple inlet and discharge

points

Totally enclosed for dusty, corrosive or hazardous

environments

screwCONVEYORS

Screw conveyors move materials either horizontally, on an incline or vertically. They are used to feed, distribute, collect or mix and can be equipped to either heat or cool while performing this transfer. With the proper cover and gasketing, they are easily made dust or weather tight and rodent proof.

Screw Conveyor Product Range

Extreme Versatility: Several options and parts

combinations are available for conveying a wide variety of materials

in many different markets.

Mixing: The normal rotation of the

screw when conveying material also lifts and tumbles the product,

which makes a screw conveyor an efficient mixer.

Simultaneous

Conveyance in Two Directions: Combining right-hand and left-hand

flights produces bidirectional conveyance.

Ready Reversibility: No

need for soft-start units.

High-temperature Materials:

Properly applied screw conveyors can handle product at temperatures

above 1000 degree F.

Abrasive Materials: Many

special materials and hard-coating options are available to extend

screw life in extremely abrasive applications.

Flood

Loading Capability: Screw feeders are very efficient and

reliable in regulating feed to downstream equipment. The screw

diameter, pitch combination, pipe size, and flight configuration can

be customized to solve specific bin unloading requirements.

Total

Enclosure Screw Conveyor Systems:

Completely enclosed systems

protect the environment from the product being handled (dust-tight)

and/or protect the conveyed material from the environment.

Large Lump Size: Within industry guidelines,

conveyance of pieces up to 7-1/2” is possible.

Multiple Inlets or

Discharges: Intermediate inlets and/or discharges are readily added.

-

- Label: screw conveyor, tubular conveyor, u conveyor, tubular screw conveyor, trough screw conveyor, mechanical conveyor, U trough screw conveyors, helicoid screw, tubular screw conveyor, conveyor, trough screw conveyor ,