HOW DOES IN LINE SIFTER WORK?

Continuous Screening Systems-Pneumatic Screen-Separators

We screen raw materials you used when storing or in the mechanical and pneumatic transport processes after storage by means of pneumatic screens operating magnetically and centrifugally, making them clean and ready for the process.

The screen type (above) used when loading the products in the silos by means of silobus and the screen used during the process (side) are different in construction.

Vibratıon Screen, Sılobus Screen, Sılo Screen

We also apply vibration and conical pneumatic screening technologies in your pneumatic transfer processes and silobuses. Thanks to the conical screens in the range of our products which are installed at the highest level of the silos, we prevent ingress of foreign objects into your silos. Foreign materials especially sand, calcite and similar materials in the construction chemicals may give damage to the screws and mixers, other transport equipment of the process. For this reason, the raw material introduced in the process should be screened definitely.

Sievıng - Maxımum control for optımal results

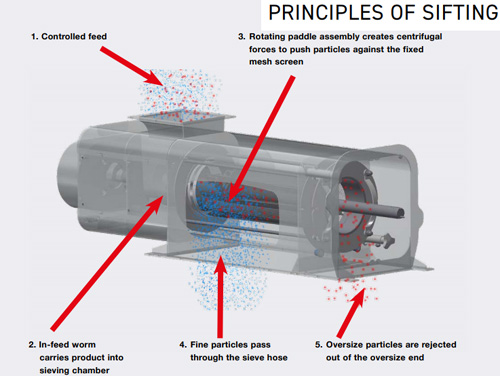

Companies in the food, feed, pharma and chemical industries are being confronted with increasingly stringent requirements with regard to food safety, quality, tracking & tracing and hazards associated with dust and explosions. So it should come as no surprise that Dinnissen Process Technology is continually searching for the best solutions when it comes to quickly and reliably managing various granulated as well as powdered materials. Effi cient fractionation ensures the highest purity Our sieving technique is based on the use of our centrifugal sieves. The material to be fractionated is brought into the sieving chamber, where the material is agitated by spinning fi ns. Those fractions which consist of small enough particles pass through the centrifugal sieve, whereas contaminants and larger particles are quickly transported onwards. By varying the rotation speed as well as the diameter of the openings and the path length of the sieve, we can realize any desired sieving result. And our broad range of accessories and options makes it possible to realize the necessary level of quality, safety and hygiene for any situation.

Screen holes range from 0.65 to 8mm. It is used in mills, bakeries and other industrial food processing, to sift wholegrain flour, cake flour, bakery flour, cornstarch, durum semolina and crystal sugar. Designed for pneumatic systems.

The material to be fractionated is brought into the sieving chamber, where the material is agitated by spinning fi ns. Those fractions which consist of small enough particles pass through the centrifugal sieve, whereas contaminants and larger particles are quickly transported onwards. By varying the rotation speed as well as the diameter of the openings and the path length of the sieve, we can realize any desired sieving result. And our broad range of accessories and options makes it possible to realize the necessary level of quality, safety and hygiene for any situation.

PDF

brochure

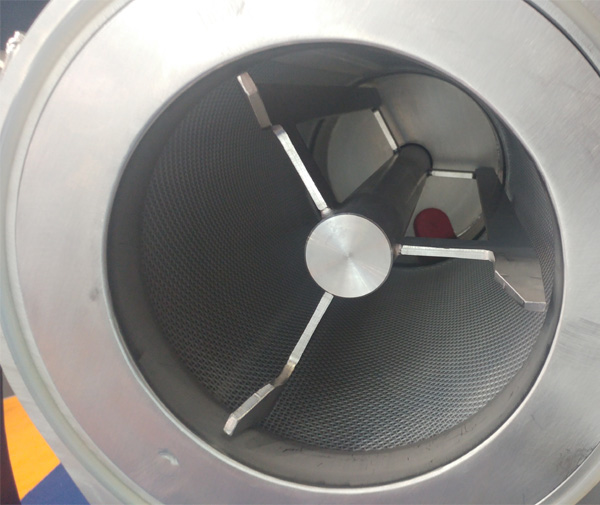

HYGENIC DESIGN SIEVE

The machine housing and the screens are completely made of stainless steel. A new tangential inlet without screws prevents product from accumulating in the inlet. This makes the inline check sieve the perfect choice for use in the finished product section.

SPECIAL DESIGN SIEVE

Material to be screened during operation is fed into the feeder port of the screen. The powder is run inside the screen to the drum section, where blades turning in the direction of the drum force the material through the drum. The material passing through the drum is ejected through the discharge port at the bottom of the screen.

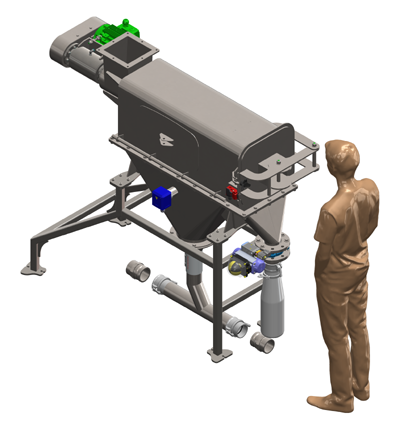

Transport capacity: 3-6 ton/h

Length:1600mm Width:1700mm

Height: 1500mm

Construction material: stainless steel

screen: different mesh sizes from 0,65

to 8mm

Debris unloading:

automatically with electropneumatic shut-off valves

Pipe

connections: 60 - 114mm diameter

Operation type: vacuum or

pressure

Drive: 3kW-5.5kW

- Lebels: sieve, flour sieve, flour sifting, powder sieve, contitinuous sieve,rotary sieve, ,cyclone,flour sifting, inline sifter, inline vacuum sifter, pneumatic conveying sifter, Centrifugal Sifter, rotary sifter,flour sifter,sieve,screening,screen, Pneumatic Conveying Cifter | Inline Rotary Sifter | Inline Sifter | Vacuum Sieve | Pneumatic Conveying Screening, turbo sifter