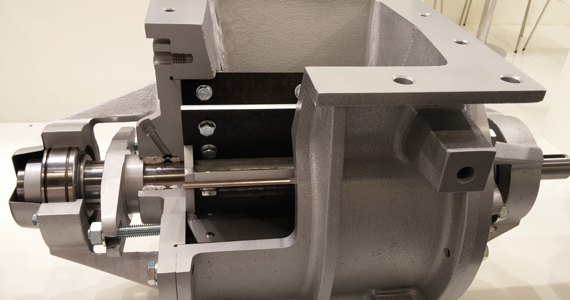

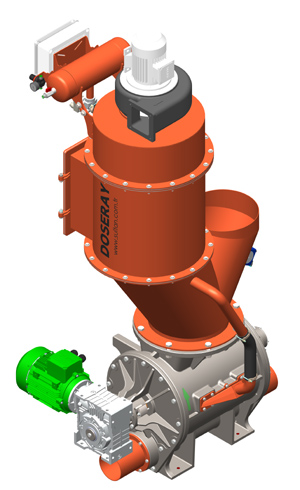

How the AIRLOCK Rotary Valve Star Feeder Valve is Used?

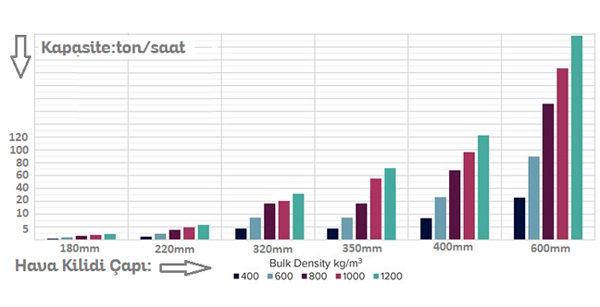

When performing transfer on all pneumatic conveying lines, it is a device to feed the material down to the line and separate the raw material pneumatically transferred from the air. Blade forms, tolerances, revolution speeds vary depending on type of process and type of the product to be transported. Likewise, it may also act as breaker depending on the characteriStics of the material to be transported. Even it may also operate coupled with the breakers.Rotary Valve AIRLOCKs are designed for use under gravity,pressure and vacuum conditions.

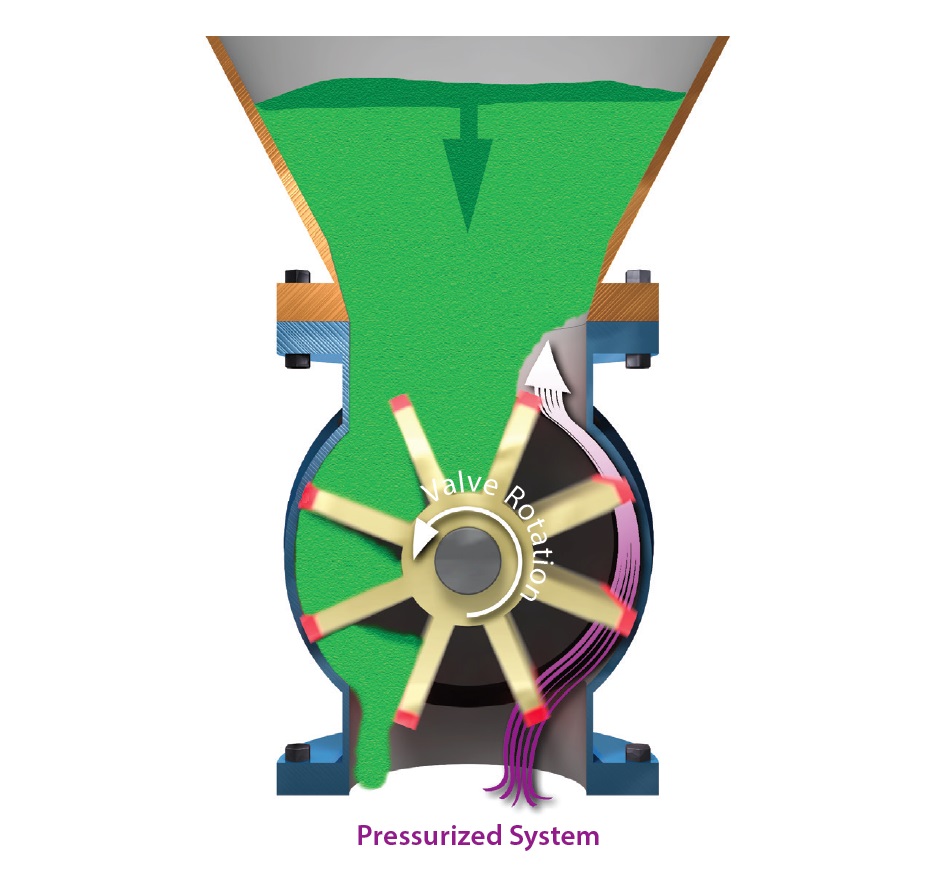

BLOW THROUGH Rotary Valve

Blo-thru Rotary Airlocks meet the specific needs of the pneumatic conveying industry, a natural extension to the Rotary Airlock; both products are used to regulate the flow of dry powder, dust or granular product, while maintaining an airlock.The Blo-thru Rotary Airlock has diStinct advantages for the specialist as it introduces high pressure conveying air through the airlock body and rotor pocket ensuring HIGH EFFICIENCY THROUGHPUT WITH LOW EFFECTIVE PRESSURE DROP.

This is achieved by the fact that more blades are in contact for longer periods with the valve body resulting in less air leakage and by blowing through the rotor each rotor pocket is efficiently emptied.

DOSERAY range of blo-thru airlocks is robustly constructed with an emphasis on close tolerances and minimal eccentricities, making the unit suitable for the majority of pneumatic conveying applications and is available is sizes ranging from 5" up to 18".

AIRLOCK, ROTARY VALVE - ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

Rotary Valve PDF brochure

Why Choose a DOSERAY Rotary AIRLOCK?

Air Filtration provides a complete line of rotary valve - AIRLOCKs

suitable for AIR LOCK applications ranging from gravity discharge

of filters, rotary valves, cyclone dust collectors, and rotary

valve - AIRLOCK storage devices to precision feeders for dilute

phase and continuous dense phase pneumatic conveying systems.

Rotary Valve / AIRLOCK Feeders are used in pneumatic conveying

systems, dust control equipment, and as volumetric feed-controls

to maintain an even flow of material through processing systems.

The basic use of the rotary valve, AIRLOCK feeder is as an AIRLOCK

transition point, sealing pressurized systems against loss of air

or gas while maintaining a flow of material between components

with different pressure. Rotary Valve, AIRLOCK Valves are also

widely used as volumetric feeders for metering materials at

precise flow rates from bins, hoppers, or silos onto conveying or

processing systems.

Blow ThrOUGH Rotary Valves

A rotary valve is of no use by itself. Rotary valve, AIRLOCKs are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, AIRLOCK Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

ROTARY VALVE AND PRODUCTS

Rotary AIRLOCK ( rotary valve) feeders have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include: cement, ore, sugar, minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, spray dryer, etc...

- Lebels: rotary valve, rotary AIRLOCK, AIRLOCK valve, rotary feeder, blow through rotary valve, flow through AIRLOCK, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary AIR LOCK valve, rotary valve producer , rotary valve price, rotary valve draw