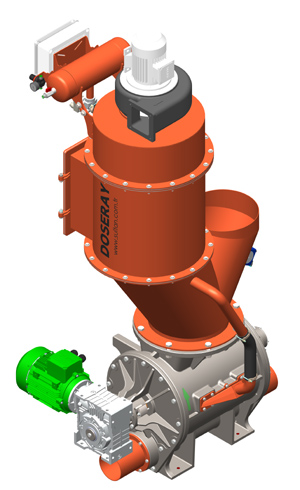

How the AIRLOCK Rotary ValveS WORK?

When performing transfer on all pneumatic conveying lines, it is a device to feed the material down to the line and separate the raw material pneumatically transferred from the air. Blade forms, tolerances, revolution speeds vary depending on type of process and type of the product to be transported. Likewise, it may also act as breaker depending on the characteriStics of the material to be transported. Even it may also operate coupled with the breakers.Rotary Valve AIRLOCKs are designed for use under gravity,pressure and vacuum conditions.

What IS A Rotary Valve?

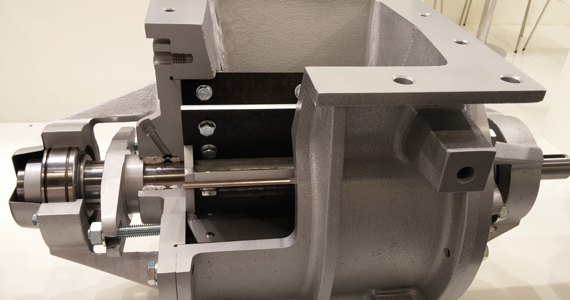

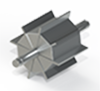

It is a compact mechanical device for continuously discharging bulk powders or granules under gravity flow. By definition it is the simplest of machines having only one moving part (ignoring the drive); a multi-vane rotor revolving in close contact in the housing and where the housing has an inlet at the top, and an outlet at the bottom.

Rotary Valve - AIRLOCKs - Star Feeder may be made of ST37 Carbon Steel and AISI-304 AISI-316 Stainless Steel. Bedding types of the AIR LOCKs may be mechanical sealing and felt, again depending on the hot process.

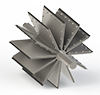

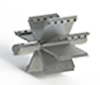

Rotary Valve - Ailock-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

Rotary Valve - AIRLOCK Star Feeder That the Cell Wheel has that many options is completely related with type of material to be transported as well as process. This is so vital that a single fault may give damage to the material to be transported. Simple solution commercially available may deliver successful results for transfer of many materials such as flour, cement and many more. However, a slight change in the granule size and a different material means fail of such equipment.

Rotary Valve , AIRLOCK Function

Our Rotary Valves, designed according to a criteria of maximum applicative

universality, are suitable for controlled feeding or discharging of products in powder or

granular form, from silos, hoppers, pneumatic conveying systems,high temperature process, bag filters or cyclones.

Rotary Valve Connection Types

How will the valve connect to your larger system, and how will it feed and discharge? These are all important specifications, as different feeding and discharge equipment can be used to differing successes. There are hopper feeders, blowers, simple piping, and other equipment, so figure out which one will be used in your project. Specifying these aspects will also allow you to find a rotary valve that will come with the correct connection characteriStics for your greater application such as welding spots, through holes, etc.

AIRLOCK, ROTARY VALVE ROTOR TYPES

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

- Rotary valves are used in almost all pneumatic conveyor

systems, but they also find uses in many other applications.

This section will display just how indispensable these valves

are, and how they can Still find new uses.

Some notable applications of rotary valves are:

Food and chemical processing applications

Pharmaceutical manufacturing applications

Abrasive product conveyance/metering

PlaStics manufacturing

Frequently cleaned/abiotic applications

Pneumatic conveyance

and more.

Rotary Valve PDF brochure

Why Choose a DOSERAY Rotary AIRLOCK?

Air Filtration provides a complete line of rotary valve - AIRLOCKs

suitable for AIR LOCK applications ranging from gravity discharge

of filters, rotary valves, cyclone dust collectors, and rotary

valve - AIRLOCK storage devices to precision feeders for dilute

phase and continuous dense phase pneumatic conveying systems.

Rotary Valve / AIRLOCK Feeders are used in pneumatic conveying

systems, dust control equipment, and as volumetric feed-controls

to maintain an even flow of material through processing systems.

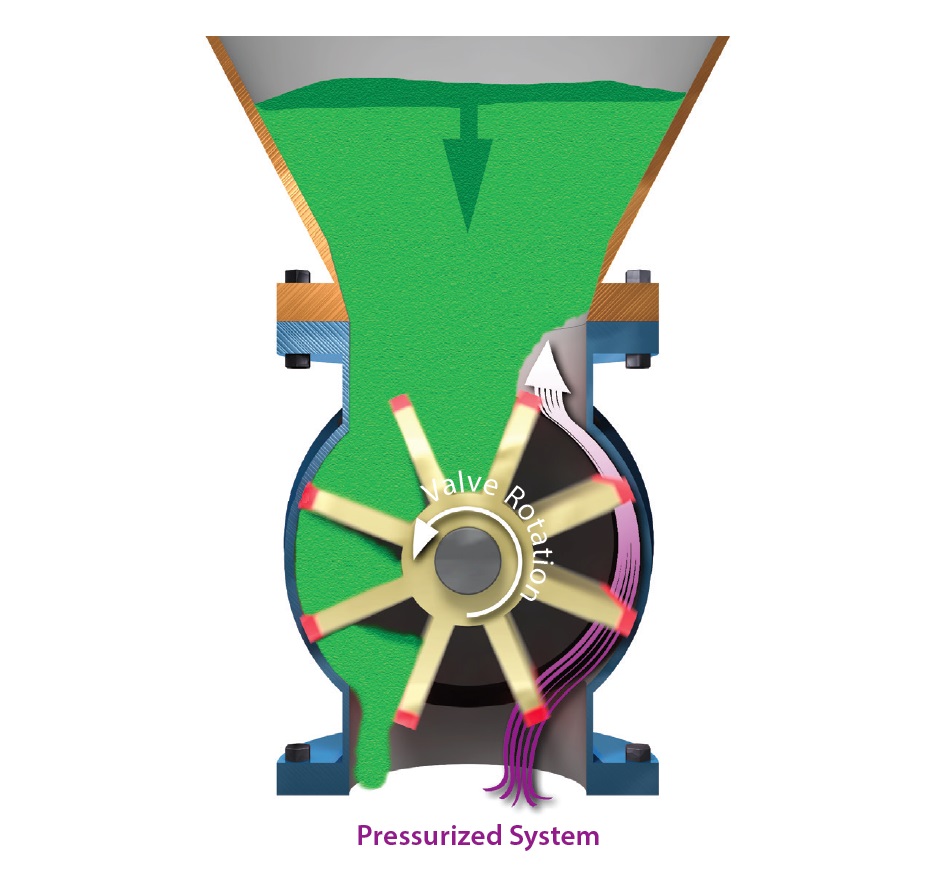

The basic use of the rotary valve, AIRLOCK feeder is as an AIRLOCK

transition point, sealing pressurized systems against loss of air

or gas while maintaining a flow of material between components

with different pressure. Rotary Valve, AIRLOCK Valves are also

widely used as volumetric feeders for metering materials at

precise flow rates from bins, hoppers, or silos onto conveying or

processing systems.

Blow ThrOUGH Rotary Valves

A rotary valve is of no use by itself. Rotary valve, AIRLOCKs

are

useful as one component in a bulk or specialty material handling

system. Rotary Valve, AIRLOCK Feeders have wide application in

industry wherever dry free-flowing powders, granules, crystals, or

pellets are used. Typical materials include: cement, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

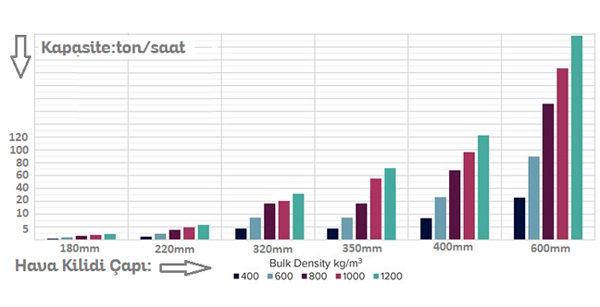

ROTARY VALVE capacıty

DOSERAY Rotary Valves are rugged and

trouble-free.They are ideal to use as feeders and air-locks for vacuum and low-pressure positive systems.

Rotary Valves help your pneumatic system achieve peak performance.

Precision-crafted to maintain proper air seals, our rotary valves

are rugged and dependable, even when youre conveying abrasives and

corrosives.

Available in many models, sizes and construction

materials, the DOSERAY rotary valve is a versatile component in most

dilute-phase pneumatic conveying and feeding operations.

Rotary airlock ( rotary valve) feeders have wide application in industry wherever dry free-flowing powders, granules, crystals, or pellets are used. Typical materials include: cement, ore, sugar, minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime, coffee, cereals, pharmaceuticals, spray dryer, etc...

- Lebels: rotary valve, rotary AIRLOCK, AIRLOCK valve, rotary feeder, blow through rotary valve, flow through AIRLOCK, silo discharge, cyclone discharge, dust collection, pneumatic conveying, rotary AIR LOCK valve, rotary valve producer , rotary valve price, rotary valve draw, rotary valve airlock,highh temperature rotary valve, rotary discharge valve,rotary airlock,wam rotary valve