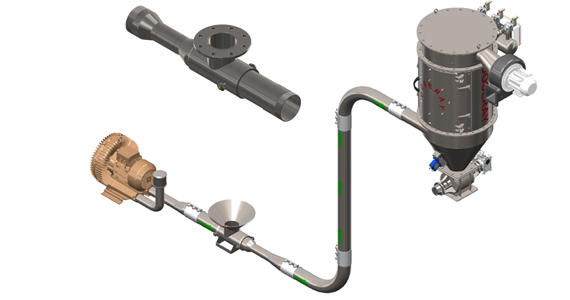

WHAT IS THE VENTURI EDUCTOR - VENTURI CONVEYING?

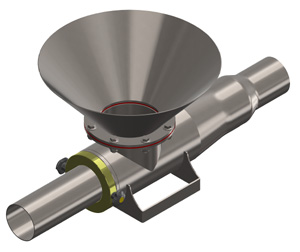

Venturi Eductors are commonly used for pneumatically conveying

material particles in the dilute phase. This type of system creates

two effects: the suction in the feed inlet and the positive pressure

that pushes the particles into the conveying system. The eductor

introduces a driving air from a source into a nozzle. This would

eventually result in a vacuum in the suction feed that will draw the

particles into the eductor. The particles are driven by the

compressed air and passed through the diffuser,and finally

discharged into the conveying system.

Eductors are an

efficient way of feeding particles like powders, flakes, abrasives,

bulk solids, and other granular particulates. With this type of

system, maintenance cost is greatly lessened through the elimination

of the conventional rotary objects used in this application. Rotary

valves do not perform well in conveying materials with very fine and

abrasive textures and that is why venturi eductors work best for

these applications.

Another advantage of this type of

conveying method is that it eliminates the Blowback effect caused by

using rotary airlocks/ rotary valves. Blowback may cause several

problems in the system and these are the wear problems when

conveying fine or abrasive particles, housekeeping problems, and

explosion hazards. In addition to this, eductors also eliminate the

harmful effects a rotary valve may cause a product, thereby

minimizing the damage and degradation of the conveyed particles

Custom Engineered Designs Venturi Eductors

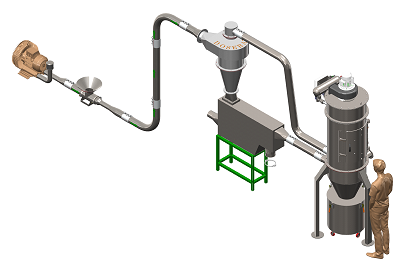

Venturi Eductor economical method to convey powdered or pelletized materials.Properly designed venturi eductor systems are reliable and require little maintenance. The systems are most valuable in conveying applications when the material is transported at arate less than 6000#/hr and over combined vertical and horizontal distances of up to 300 feet in totallength.Venturi eductor systems are positive pressure dilute phase pneumatic systems that can convey a variety of bulk solids materials. The venturi eductor replaces the rotary valve that is normally used as an airlock and feeds material into the pneumatic conveying line. The problem sencountered when using rotary valves,like air blow back and pellet clipping,are eliminated with the venturi eductor.

PDF

brochure

HOW DOES IT WORK VENTURI EDUCTOR?

Eductors use the

vacuum created by the venturi to introduce the bulk solids into

the conveying line. Technological advances realised by DOSERAY

will allow you to use an affordable air source provided either by

a regenerative blower or a positive displacement blower while

conveying without the need for a rotary airlock.

TeSting is

available in our lab with your products. Our eductors are fully

refundable should you not be totally satisfied with its

performance.

.

In the dilute phase pneumatic conveying with eductors the

Venturi effect is exploited in order to obtain a double

effect: it creates a negative pressure at the feed inlet from

which the material is sucked and then pushed into the line

pressure (pull-push).

Dilute pneumatic conveying

eductors

This results in a system with no moving parts and

characterized by a fast installation and subStitution that

makes this solution among the most economic both as an

investment and in terms of maintenance costs.

The

range of available Venturi Eductors is very large and makes

this handling system compliant with the most varied kinds of

materials and industrial processes.

However, it is of

the utmost importance that the system is designed remaining

in the operational limits to maximize the benefits of this

technology, without causing operational difficulties and

unnecessary energy costs.

FOOD PROCESSING INDUSTRY

The food processing industry uses venturi eductor based pneumatic conveying systems to drive milk and non-dairy powder spray dryers. They are also used to transport products in processes that include.

CHOOSING THE BEST CONVEYING METHOD WHEN BUILDING NEW

PLANT

Engaging experienced design experts is ideal

when implementing the installation of a pneumatic conveying

system within a new plant. They can help determine if the system

can work with venturi eductors from the start. This will avoid

having to retrofit the plant later if it was wrongly designed at

first with rotary valves or electric pumps.

Venturi Conveyor Benefits

For example when at the discharge from a micro doser is important not to negatively affect the dosage, as in the case of back pressure generated by air leakage through a rotary valve, in the classic dilute phase pressure conveying.

Or when to download a big bag is advantageous to suck from the empty big bag to prevent loss of material in the environment on the occasion of subStitution, while maintaining a transfer of product via pneumatic pressure Conveying.

Finally we mention one of the most effective applications of use of this technology, the discharge from a cyclone separator, again thanks to the suction Venturi effect, which increases the performance of dust abatement up to 100% efficiency.

Continuous conveying

• No blow-back

• No rotary airlocks – No mechanical shearing

• No maintenance

• No Moving Parts

• Air pressure from 0,2 to 0,9 Bar

• Environmental protection

• Easy to be installed on exiSting plants

- Lebels: venturi eductor, venturi conveying, venturi ejector, venturi pneeumatic conveying, venturi transfer