WHAT IS THE ROTARY VALVE?

Rotary feeders (also known as rotary airlocks or rotary valves)

are commonly used in industrial applications

as a component in a bulk or specialty material handling system.

Rotary feeders are primarily used for discharge of bulk solid

material from hoppers/bins, receivers, and

cyclones into a pressure or vacuum driven pneumatic

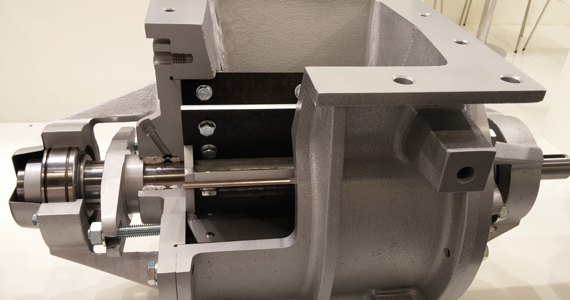

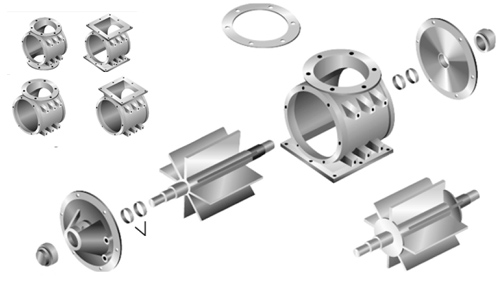

conveying system. Components of a rotary feeder include a

rotor shaft, housing, head plates, and

packing seals and bearings. Rotors have large vanes cast or welded

on and are typically driven by small IC

engines or electric motors. Rotary airlock

feeders have wide application in industry wherever dry free-flowing

powders, granules, crystals, or pellets are used. Typical

materials include: cement, ore, sugar,

minerals, grains, plaStics, dust, fly ash, flour, gypsum, lime,

coffee, cereals, pharmaceuticals, etc...

Industries requiring this type are cement, asphalt, chemical,

mining, plaStics, food, etc... Rotary feeders

are ideal for pollution control applications in wood, grain, food,

textile, paper, tobacco, rubber, and paint industries, the

Standard Series works beneath dust collectors

and cyclone separators even with high temperatures and

different pressure differentials.

Rotary valves are available with square or round inlet and outlet

flanges. Housing can be fabricated out of

sheet material or cast. Common materials are cast Iron, carbon

steel, 304 SS, 316 SS, and other materials. Rotary airlock

feeders are often available in standard and

heavy duty models, the difference being the head plate and bearing

configuration. Heavy duty models use an outboard bearing in

which the bearings are moved out away from

the head plate. Housing inlet and discharge configurations are

termed drop-thru or side entry. Different wear protections

are available such as hard chrome or ceramic

plating on the inner housing surfaces. Grease and air purge fittings

are often provided to prevent contaminants from entering the

packing seals.

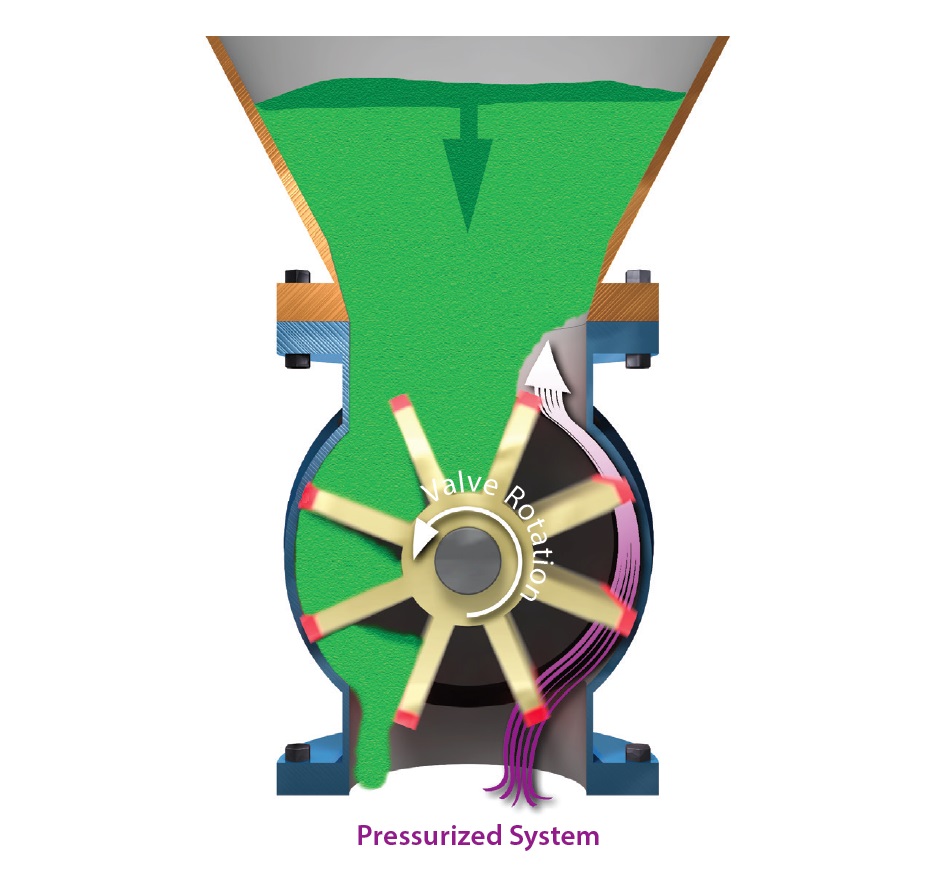

The basic use of the rotary airlock feeder is as an airlock transition point, sealing pressurized systems against loss of air or gas while maintaining a flow of material between components with different pressure and suitable for air lock applications ranging from gravity discharge of filters, rotary valves, cyclone dust collectors, and rotary airlock storage devices to precision feeders for dilute phase and continuous dense phase pneumatic convey systems. Drop Thru rotary airlock feeders are designed for rugged applications that require an outboard bearing style unit where contamination and /or an abrasive product cannot be handled with an inboard bearing style. The outboard bearing feeders is engineered for use in high pressure pneumatic conveying systems, with high temperatures where more of an effective seal is required due to high or excessive wear that is experienced with a simple dust collector

• Rotary Valve

Rotary airlock feeders/ rotary

airlock valves are used in pneumatic conveying systems,

dust

control equipment, and as volumetric feed-controls.

•

Volumetric Feeder

Rotary airlock valves are also widely

used as volumetric feeders for metering materials

at precise flow

rates from bins, hoppers, or silos onto conveying or processing

systems

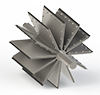

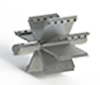

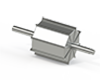

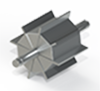

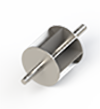

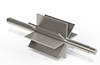

AIRLOCK ROTARY VALVE - ROTOR TYPE

-

- Rotary Valve - Ailocks-Star Feeder internal Rotors have options such as blade, rounded type, adjusted blade type, stripper and polyamide.

PDF

brochure

ROTARY VALVE

A rotary valve is of no use by itself. Rotary valve, airlocks, and

rotary valve are useful as one component in a bulk or specialty

material handling system. Rotary Valve, Airlocks Feeders have wide

application in industry wherever dry free-flowing powders,

granules, crystals, or pellets are used. Typical materials

include: cement, sugar, minerals, grains, plaStics, dust, fly ash,

flour, gypsum, lime, coffee, cereals, pharmaceuticals, etc...

blow thru rotary valve

While pneumatic transport processes differ according to the phases, it may also diffrent in the same phase. Low pressure, that is dilute phase transfer, can be categorized under 2 classes, namely vacuum and pressure. This classification shows, even slightly, differences in the rotary valve - airlocks. Consequently, we perform manufactures according to the air locks to be used on the vacuum and pressure line.

PRODUCTS

Rotary airlock feeders have wide application in industry wherever dry

free-flowing

powders, granules, crystals, or pellets are used.

Typical materials include: cement,

ore, sugar, minerals, grains,

plaStics, dust, fly ash, flour, gypsum, lime, coffee,

cereals,

pharmaceuticals, etc...

- Lebels: rotary valve, rotary airlock, airlock valve, rotary feeder, blow through rotary valve, flow through airlock, silo discharge, cyclone discharge, dust collection, pneumatic conveying, cement rotary valve, fly ash rotary valve