MICRO-INGREDIENT DOSING SYSTEMS

The automatic management of micro-ingredients ensures a

consistent dosing of products thus eliminating any product waste

resulting from manual handling with bags. Moreover, it allows

you to keep the premises clean, in compliance with the HACCP law

provisions in force on hygiene and safety in the workplace. With

such a system, a single operator is more than sufficient to

facilitate the entire ingredient loading operation and manage

the recipe from the electronic PLC control panel. All weighing

phases are performed automatically at the end of the cycle which

allows the operator to use the accurately weighed product. High

dosing accuracy and the versatility of the micro-ingredient

dosing station ensures reliable and infinitely repeatable

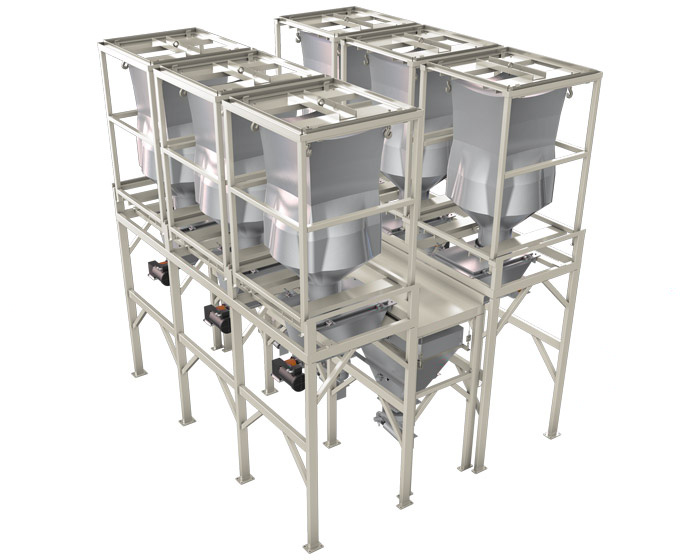

results. The systems are also completely modular allowing for

gradual expansion of the system to include storage and dosing of

more liquid and/or powdered ingredients.

PDF

brochure

process

.

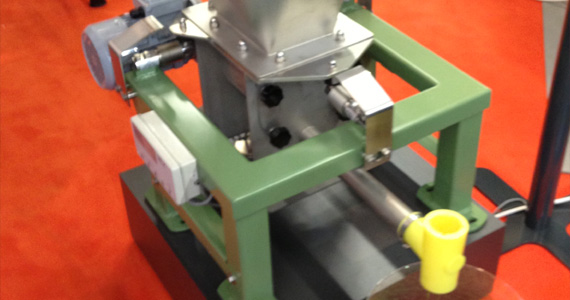

- RDOSERAY is a leading manufacturer of food processing and

animal feed processing equipment. The DOSERAY micro

proportioning system DOS is used for high precision dosing of

micro-ingredients in animal feed such as vitamins, additives

and trace elements. It is applied to the production of

premixes, formulated feeds, aqua feeds and pet foods. Other

main fields of application are the chemical, pharmaceutical

and food processing industries.

Designed to deliver precise weighing and dosing of ingredients

The DOS achieves the accurate weight required for each ingredient.

The DOS automatically eliminates discrepancies in weighing results.

Superior sanitation with stainless steel.

The complete emptying of even sluggish material from the storage containers lowers the risk of contamination.

The product's high sanitation standard improves the safety of the plant by reducing the accumulation of dust that can cause explosions.

All parts in contact with the material are of stainless steel, further ensuring high sanitation standards.

Intelligent features for higher operational flexibility and productivity.

The micro proportioning system DOS allows for less frequent use of the hand intake station, where manual emptying of bags is required. This results in fewer errors, less work and less wastage.

The micro proportioning system adapts to the ingredient characteriStics for dosing of both fine and coarse particles, enabling higher process flexibility.

Advantages:

Easy dosing system, fast and

accurate

Traceability of manual steps

Direct transfer of

data to process your order (Profibus etc.)

Tolerance control

Predefined / Automatic tare

Storage of thousands product pages

Operating principle:

The preparation

table is provided with a control panel connected to the general

network. It displays the instructions stored in the database of

the recipe and guide, step by step, the operator who selects each

product to be determined by lot number or by using a barcode

reader. The system verifies that the weighed product meets the

defined tolerance.

Features

High accuracy in weighing

Flexibele formulation

Fully automatic controlled proces

Dustproof design