SPECIAL FILTER PROCESS

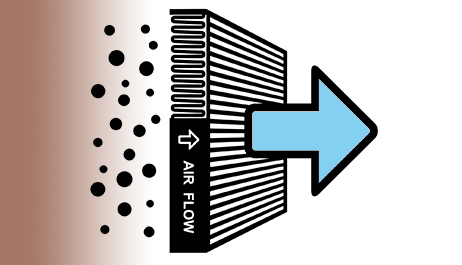

Honestly, it would be wrong to claim that we offer a cyclone

solution to all filters. The general working principles of the

cyclones and separators are in form of separation of air from dust.

During such separation process, the filter element should always be

cleaned in certain intervals. Otherwise, it becomes full and fails

to serve. For this reason, the filters should be cleaned regularly.

The cleaning operation is performed by vibrator or air jets. The air

used in the filter jets should be conditions in the same manner,

especially in the conditioned processes; we produces filters of

specific characteriStics according to the powder granular size,

working capacity and other information provided by you.

AFILTER TECHNOLOGY

-

Features

stainless steel cylindrically shaped body with bottom flange

Filter surface: 1 ~ 48 m² (11 ~ 517 sq ft)

Air volume: 60 ~ 4,500 m³/h (35 ~ 2,650 cfm)

Easy maintenance and filtering element replacement

Multifunctional, intelligent electronic control panel

Filter elements: round bags, elliptical bags, cartridges

Comfortable maintenance height

Compressed air jet cleaning system integrated in top cover

High cleaning efficiency due to "Full Immersion" solenoid valves incorporated in corrosion-resistant air tank for low-on-maintenance operation

Safe weather protection cover with lockable quick release

Tool-free filtering element removal

Increased durability

Reduced maintenance costs

Hygienic operation

Increased work safety

Low operating costs

Exceptional price-quality ratio

PDF

brochure

JET- PULSE FILTER

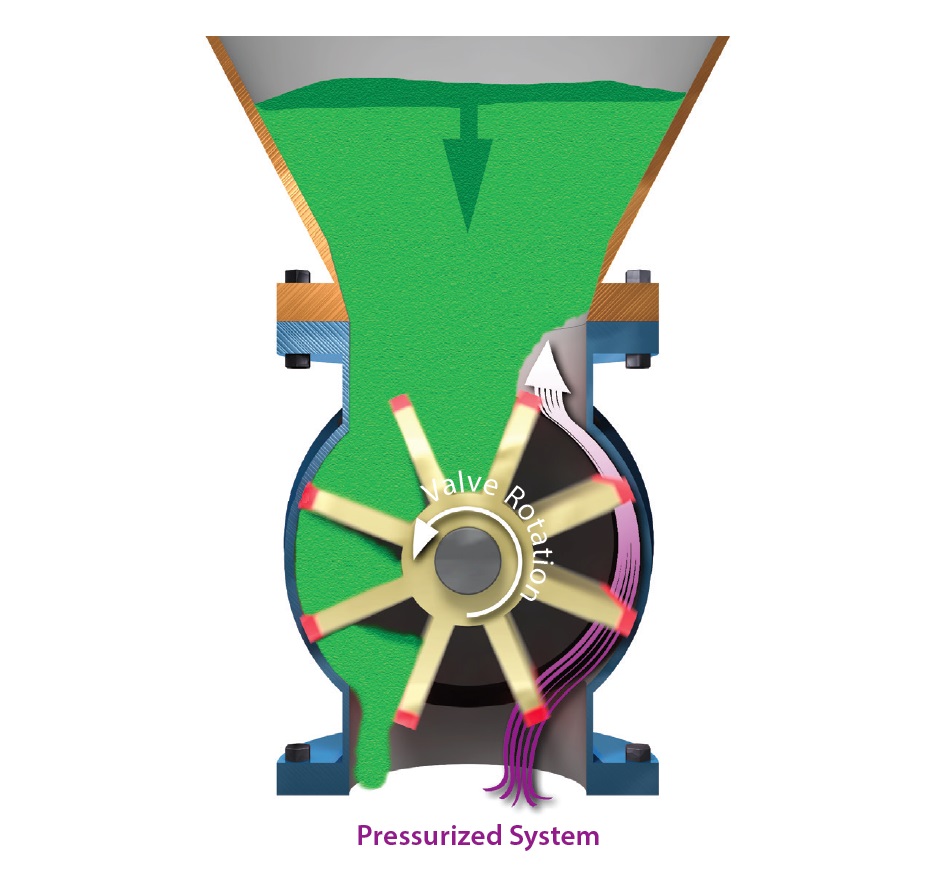

A rot raw materials which you may transport by pneumatic or

mechanic transport method are powder and granular, it is definite

that dust raises in the environment after it is introduced in the

process. In order to prevent it and separate the material from the

air, it is required to use dust separators or so-called filters.

FILTER DESIGN

WThese products are filters designed to operate at

maximum temperature of 150-250oC and separate particles 1-5 microns

in size, having large dust holding filters in small diameters.

Additionally, depending on the process to be used, 1- Surface

Polishing, 2-Calender, 3- Teflon Impregnation, 4- PTF coating ad 5-

Special resin covering operations are performed to provide the most

efficient pneumatic transfer operation.

The reason is that we know a good dust holding system is one of the

most important aspects for pneumatic transfer. For this fact, we

cooperate with the best international and national trademarks (WAM,

LETHANBEURGER, MIX and KEK are the registered trademarks of the

companies).

fılter process

- Lebels: rotary valve, dust filter, dust filters,jetpulse filter, jet-pulse, powder filter, silo filters ,cyclone